Udokan Plant's successful “on-load” commissioning in Primary Crusher Building and all conveyor areas.

The primary crusher building is a cast-in-place structure of multilevel sections of about 20 meters in height.

The primary crusher building is a cast-in-place structure of multilevel sections of about 20 meters in height.It is used to crush the ore being fed from Zapadny pit down to a size of 350 mm. The crusher capacity is over 2K tons of ore per hour. The motors on the crusher, feeders and conveyors are have VFDs designed to soft-start the equipment and control the belt speed. All the operating parameters of the crusher and conveyor are controlled from the automated operator’s room, where they can be monitored in real-time mode.

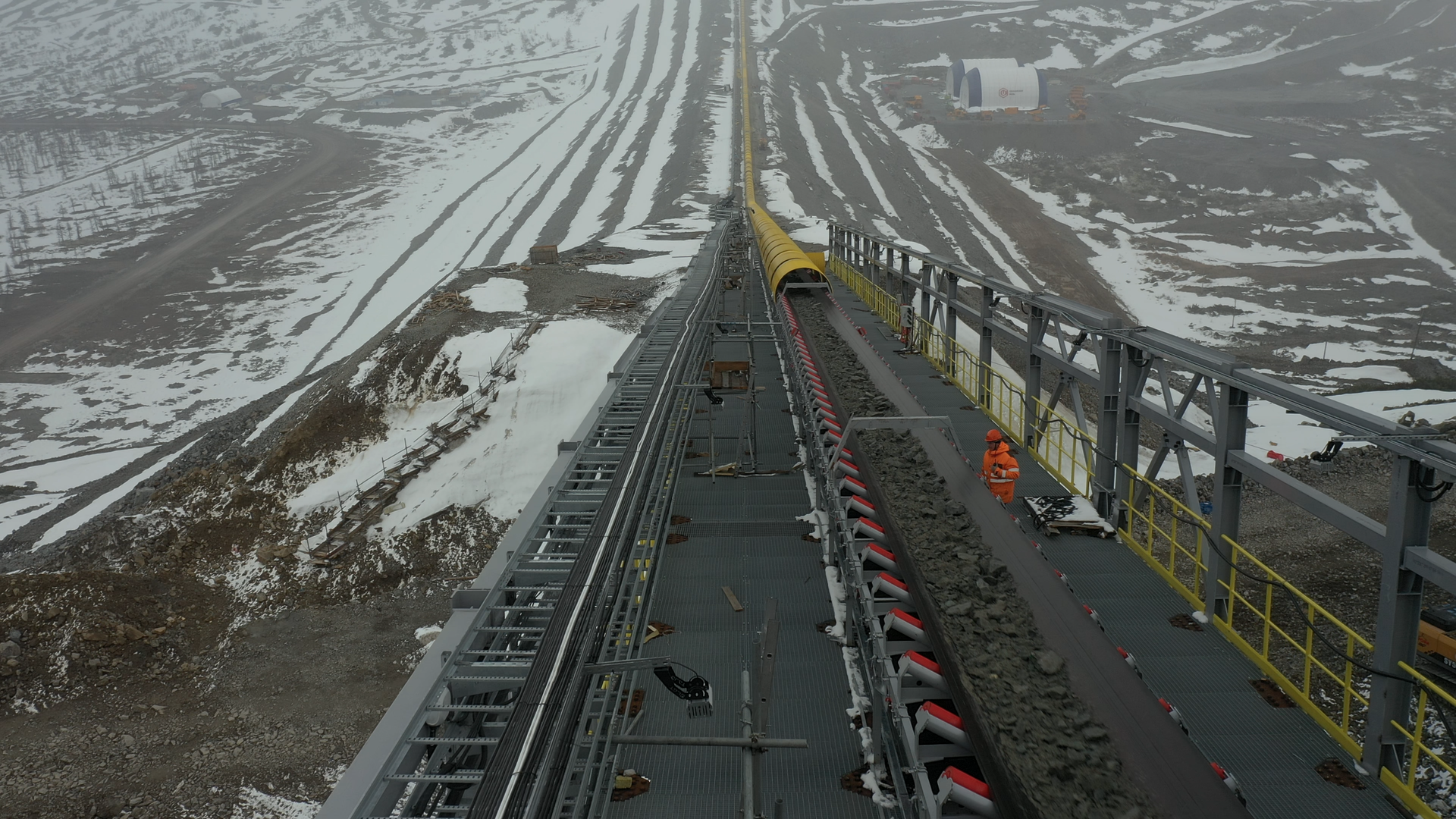

Once crushed, the ore is fed to the concentrator plant by a conveyor consisting of 3 lines, whose overall length is 2.8 km.

BelAZ haul trucks were used during test runs to fill the crusher feed hopper with ore.

The ore was fed onto conveyor, incrementally loading it from 20 % up to 100% to adjust the parameters of all units and equipment, and tune the plant automation system.

As was noted by Mr. Alexey Yaschuk, Udokan Copper's CEO, the successful start-up was the product of labor of a multitude of specialists, and above all constructors, commissioners, process engineers. “We are down the final straight to put Udokan Plant into operation” – he said.